-40%

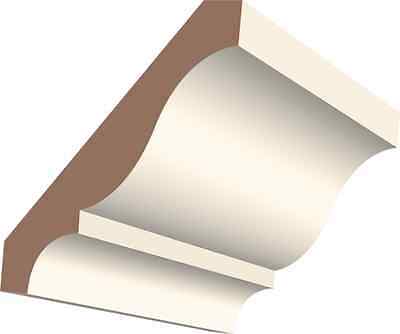

Fleur de lis- Pressed Onlay #PONL-08-20RW

$ 18.21

- Description

- Size Guide

Description

One 19-7/8" wide x 5/16" deep x 3-7/8" tall Pressed Fleur de Lis OnlayRubberwood will stain or paint. In the maple family

One 19-7/8" wide x 5/16" deep x 3-7/8" tall Pressed Fleur de Lis Onlay

- Rubberwood.

What is Rubberwood? Rubberwood is a hardwood from the maple family of woods Rubberwood has very little tendency to warp or crack Rubberwood-Eco Friendly! Rubberwood is often the most misunderstood species of wood in the furniture industry. The name rubberwood invokes a variety of misconceptions as to it's features and to it's durability. Rubberwood (also called Parawood in Thailand) is the standard common name for the timber of Hevea brasiliensis. In fact, rubberwood is one of the more durable lumbers used in the manufacturing of today's home furnishings. As a member of the maple family, rubberwood has a dense grain character that is easily controlled in the kiln drying process. Rubberwood has very little shrinkage making it one of the more stable construction materials availabe for furniture manufacturing. Like maple, rubberwood is a sap producing species. In the case of maple, it is sap; in the case of rubberwood, it is latex. Rubberwood produces all the latex used in the world for all rubber based products. There is one more important feature of rubberwood that is very important in today's world.

Rubberwood is the most ecologically "friendly" lumber used in today's furniture industry. After the economic life of the rubber tree, which is generally 26-30 years, the latex yields become extremely low and the planters

then fell the rubber trees and plant new ones. So, unlike other woods that are cut down for the sole purpose of producing furniture, rubberwood is used only after it completes it's latex producing cycle and dies. This wood is therefore eco-friendly in the sense that we are now using what was going as waste. Do not mistake the name rubberwood when it comes to its quality features.